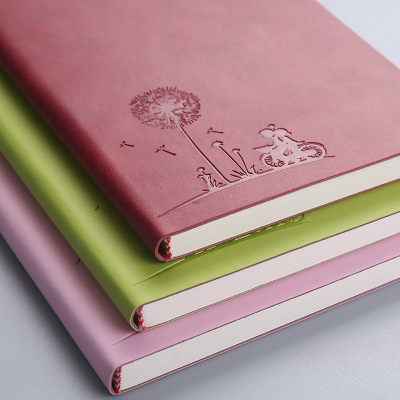

Partial UV varnishing is a technique for surface finishing of printed matter. According to the needs of product

varnishing, partial varnishing is applied to the areas where trademarks and packaging prints need to protrude. Compared

with the surrounding patterns, the varnishing pattern is more vivid, bright and three-dimensional. Extinction, partial

refraction,partial frost, partial light, partial ice, partial wrinkles, and colorful. Partial UV varnishing is mainly used in the

finishing of book covers and packaging products, making printed products more icing on the cake and more popular.

Partial UV varnishing can be performed in two stages, either retroperitoneally or directly on printed matter.

However, in order to make the effect of local glazing more obvious, it is generally performed after the printed film

is covered, and most of it is covered with a matte film.The main difference between partial varnishing and full-plate

varnishing is that one is that there are certain registration requirements for the glazing equipment, and the other

is that a printing plate needs to be made. There are three main elements of local UV glazing, equipment registration,

glazing plate and curing equipment. In order to ensure that the size of the partial UV varnishing is consistent with

the size of the printed graphics, a photosensitive imaging method should be used when making the coating plate.

According to the different printing methods, partial glazing can be divided into the following categories.

1. Screen printing partial varnishing

Screen printing has the characteristics of high ink transfer, thick ink layer and strong three-dimensional

impression. Screening screens are generally suitable for 200-300 mesh screens (lower meshes for local frosting and

local colorful effects, etc.), and the tension of the stretched screen is 20-25 N / cm. Because the equipment

investment is not large. Many books and magazines and packaging factories prefer screen printing when increasing

local coating business. Some professional printing and varnishing companies aim to improve the varnishing accuracy

and improve production efficiency. Already using a fully automatic cylinder screen printer. Production speed can reach

3000 sheets / hour. However, the partial printing of screen printing basically adopts the offline production mode.

There are fewer online screen printing units.

2. Partial varnishing of flexible plate

Flexographic printing is characterized by the ability to form thicker coatings in a simpler process. Therefore,

it is very popular in UV glazing. Partial varnishing of flexographic printing is divided into ordinary flexographic

printing varnishing and special flexographic printing varnishing,and some simple graphics are still using engraved rubber

relief. Flexographic printing partial coating is suitable for offline coating and online coating can also be realized.

Adopting flexographic printing varnishing method, combined with anilox roller and cavity scraper, can accurately

control the amount of varnish, and the varnishing quality is stable.

3.Gravure partial coating

Gravure printing is also advantageous in local uV varnishing due to the thick printing ink layer and high

resistance of the gravure cylinder. Especially the emergence of sheet-fed gravure printing machines has contributed

to the development of local varnishing. However, due to its higher platemaking costs, it is mainly used for long-term

glazing services.

4.Other local glazing methods

No one will use offset printing before UV varnish appears because its printing ink layer is too thin. The

UV varnish has a thicker film layer, higher gloss, and has the advantage of high overprint accuracy. It also has

some applications in local UV varnishing, but is mainly used for online varnishing.

Shenzhen Height-led is a device manufacturer specializing in the development, production,and sales of uvled

curing equipment. Its main products are uvled point / linear / area light sources,uvled curing furnaces, uvled curing

machines, and uvled spot curing. Machine and other curing equipment, products are exported to home and abroad, quality

assurance, welcome to buy.